Paint Spray Booths

Introduction

This article will take an in-depth look at paint spray booths.

The article will bring more detail on topics such as:

- What is a Spray Booth?

- Common Construction Principles of Spray Booths

- Types & Configurations of Spray Booths

- Applications and Benefits of Spray Booths

- And Much More…

Chapter 1: Principle of Paint Spray Booths

This chapter will discuss what a spray booth is, its common construction design, and its principle of operation.

What is a Spray Booth?

A spray booth (also known as a paint spray booth or paint booth) is a specially built enclosure designed to accommodate spray paint spraying operations and isolate and remove overspray and vapor produced during the spray application process.

Corrosion-preventative coatings are applied to metal surfaces using spray techniques. Spray booths are usually built to be fire and explosion-proof and are intrinsically safe. When doing surface preparation or coating activities outdoors or in an exposed interior space is impractical, a spray booth is often used. This could be due to various reasons, including poor weather or atmospheric conditions, environmental dangers linked with the coating to be applied, worker preference, temperature regulation, and vapor confinement.

A pipe that needs to be protected with a coating application, for example, could be at sub-zero temperatures. Workers may not be able to conduct coating tasks in such conditions. Furthermore, some coatings may be reactive at such temperatures, freezing, vaporizing, or even liquifying. As a result, spraying the coating in a temperature-controlled spray booth enclosure is an option.

Construction of a Spray Booth

The construction of a spray booth involves components such as:

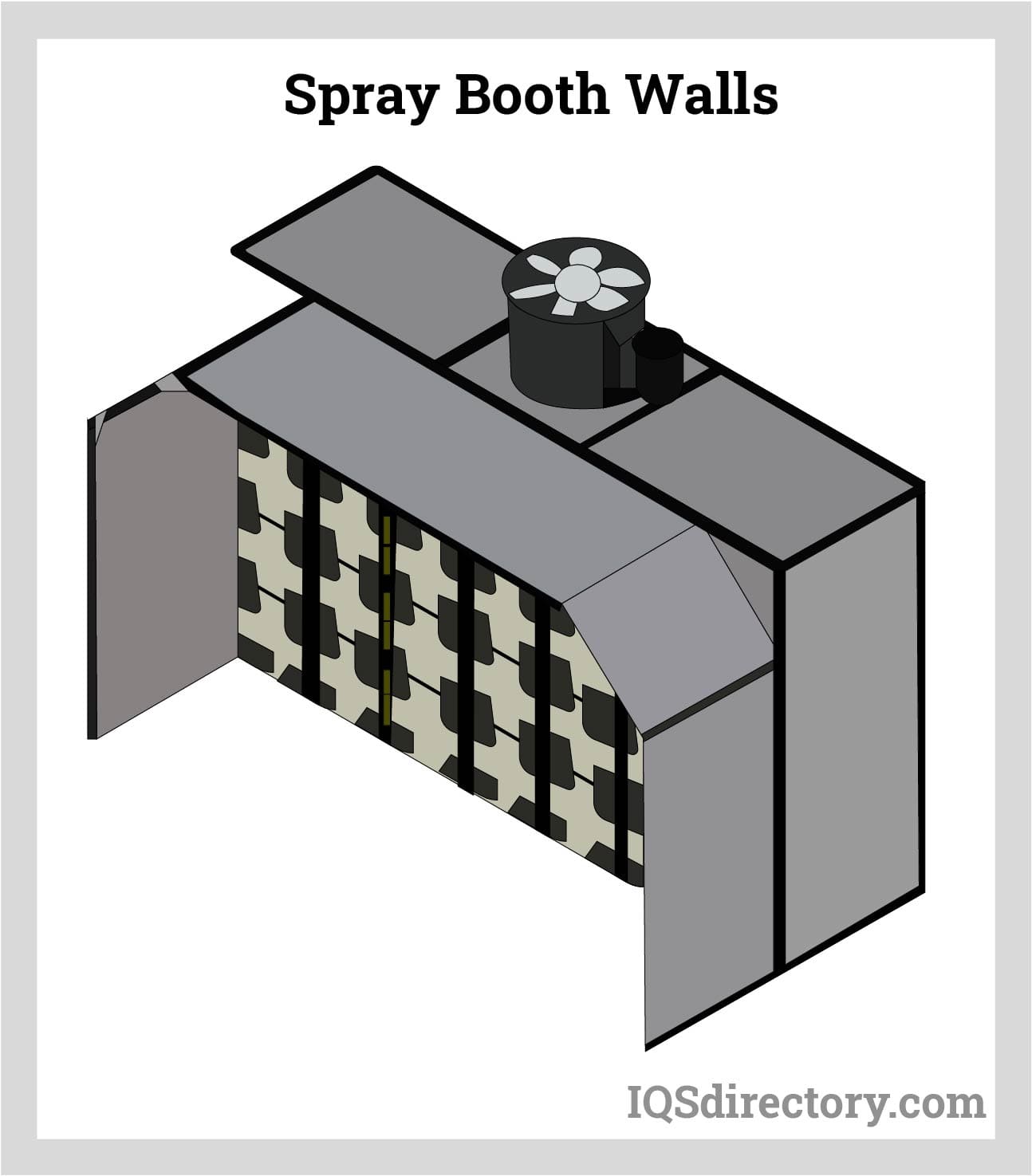

Spray Booth Walls

Paint booths have either single-skin or dual-skin walls. In terms of quality and cost, both offer advantages.

Single-skin panels are tough and robust, saving money without sacrificing quality. The external flanges provide a smooth inner surface, making cleaning the inside walls of a single-skin spray booth simple.

For a stronger, longer-lasting paint booth, dual-skin panels provide a smooth fit and finish. They're insulated to keep hot air inside the cabin while reducing noise and ambient heat outside the spray booth.

White pre-coated walls are common in dual-skin booths and may be available as an option in single-skin booths. The reflectivity of the lights is increased by white walls, making it easier to see what you're painting.

Spray Booth Doors

Vehicles, parts, and products can enter the paint booth for spraying through product doors. Whether or not a paint booth will be pressured will affect the type of product door included. The question of whether the spray booth is under negative or positive pressure related to the outside environment is at the heart of the debate. Dirt and debris cannot enter the working chamber under positive pressure and soil the object being painted. Negative pressure, on the other hand, keeps emissions and volatile organic compounds (VOCs) out of the room adjacent to the working chamber.

Filtered product doors are available in non-pressurized paint booths. Contaminants are kept out of the paint booth thanks to a series of intake filters. On pressurized paint booths, solid doors are needed because air enters the booth via a filtered intake plenum.

Roll-up doors, which come in galvanized steel, aluminum, and cloth, are another option for enclosing pressure paint booths. When space is limited or used as part of a side-load finishing system, these doors are ideal. To keep overspray from exiting the paint booth, they use a triple-layered cloth and an airtight closure. To achieve cure temperature criteria, air between layers of cloth helps maintain acceptable heat levels inside the spray booth. Painters get quick and easy access to the booth thanks to personnel doors. The paint booth's door can be found on either side. On personnel doors, observation windows may be an option.

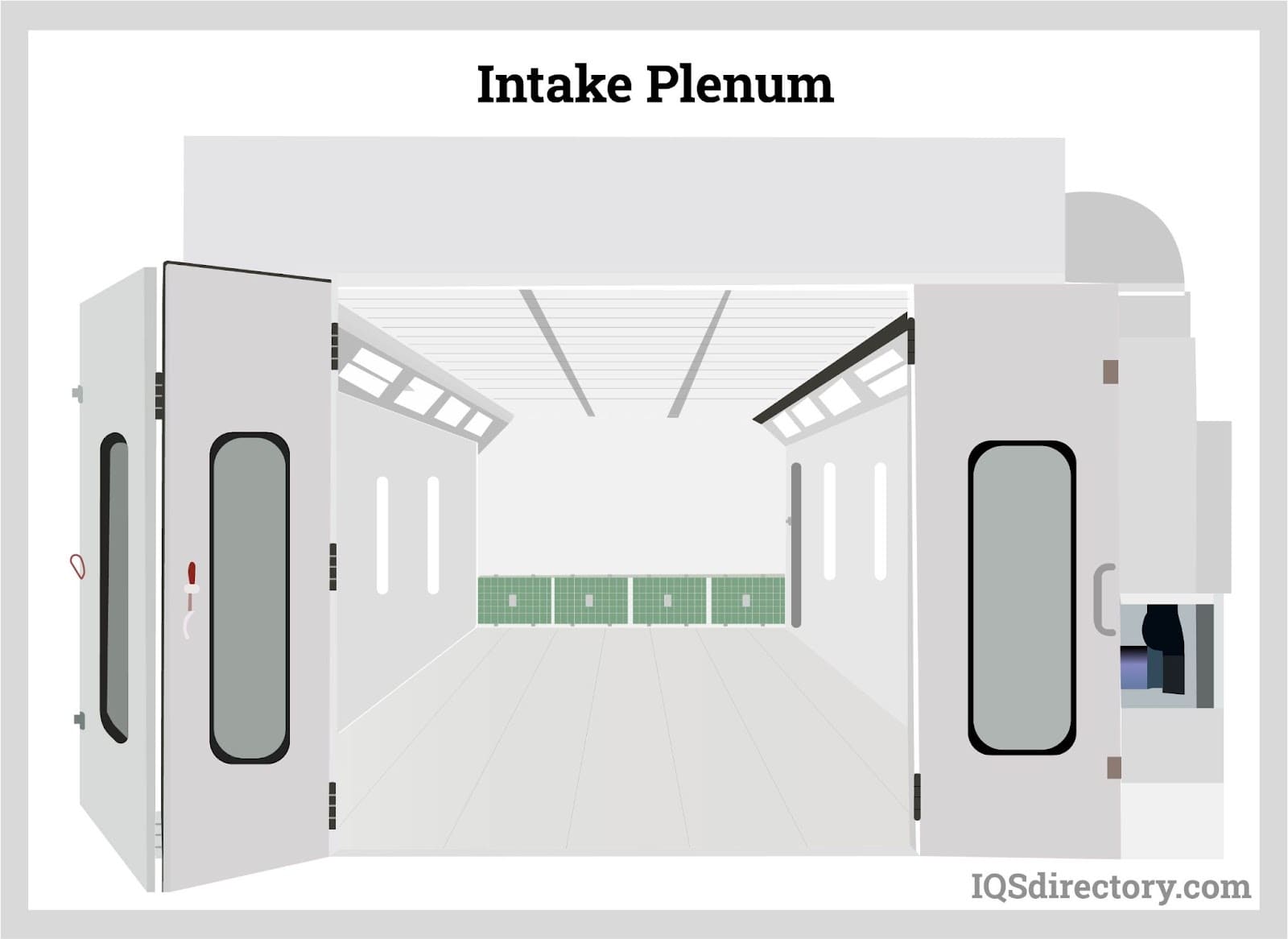

Intake Plenum

Situated in front or on top of a pressurized spray booth, an intake plenum is a system via which air is supplied into the booth. Air entering the spray booth via the intake plenum may flow parallel to the floor or downwards from an overhead plenum at the top of the chamber. High-efficiency paint booth filters are installed in the intake plenum to eliminate dust and dirt before it reaches the spray booth.

The intake plenum could be vertical at one end of the spray booth. It could also be horizontal, with part or all of the paint booth's roof as an aperture. The intake plenum is positioned at the front of the enclosure in cross-draft spray booths.

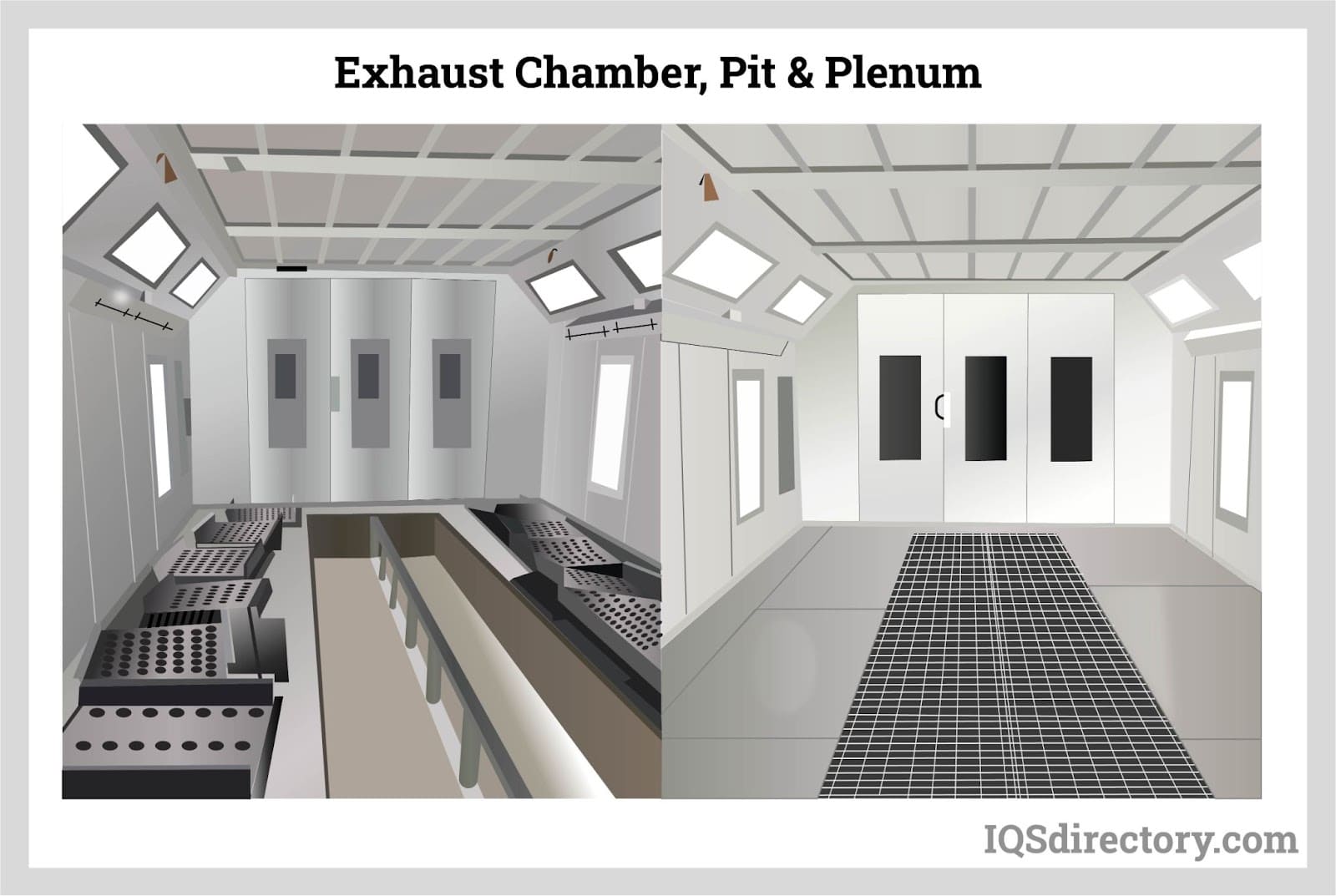

Exhaust Chamber, Pit & Plenum

A paint booth's exhaust plenum is a system for removing air from the booth. A filter mechanism in the exhaust chamber collects particles before they are released into the atmosphere. An exhaust fan sucks air from the paint booth's working chamber and pushes it through the exhaust filters and exhaust chamber. The air is subsequently vented to the outside via exhaust ducting.

The exhaust plenum is positioned at the back of the spray booth in the cross-draft and semi-downdraft paint booths. Filtered exhaust plenums are positioned on both edges of the spray booth inside downdraft paint booths.

In downdraft paint booths, air reaches the floor and is discharged through a filtered exhaust pit. One, two, or three rows can be found in the pit. It is classified as ductwork and must be built to meet the paint booth's airflow needs. In a downdraft spray booth, the exhaust plenum is situated at the back of the booth or on either side.

The primary goal of exhaust filtering is to protect the fans, stack, and plenum of a paint booth from overspray pollution while not slowing down airflow. To prevent regularly having to replace paint booth filters, exhaust filters must store enough paint. They're in the back of the spray booth's plenum, in the pit, or in the side downdraft exhaust.

Paint booth filters often feature multiple layers with increasing efficiency per layer. Paint-splattered air is trapped on the surface and in the depths of the medium. The trapping process with the multiple layers increases the life of the filter and lowers running costs. Wave paint booth exhaust filters are suitable for a wide range of paints and spray applications, from clear coatings to high solids.

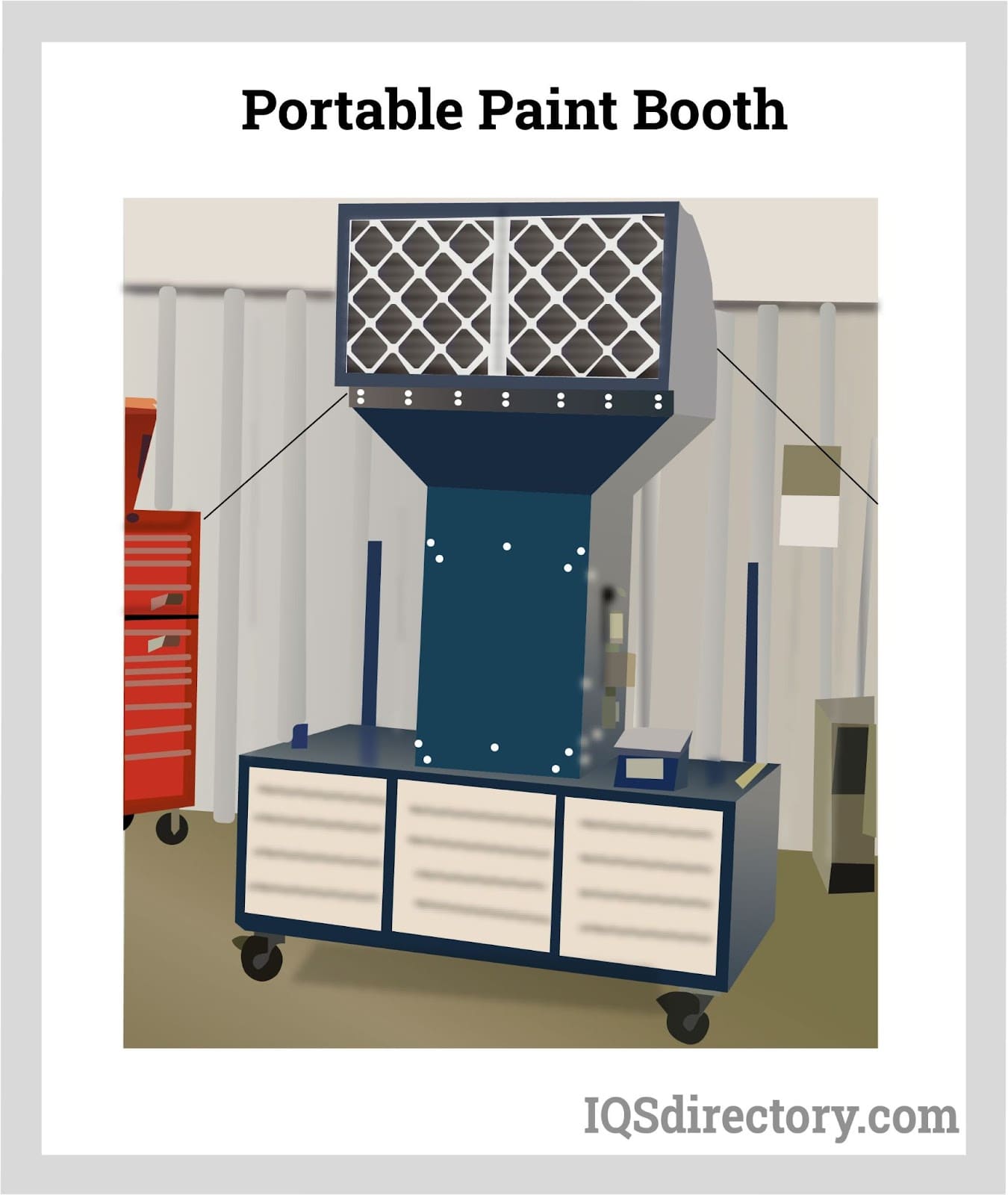

Portable paint booths often use multiple filter banks, including pre-filters, overspray capture filters, and carbon filters, to accommodate recirculation of the air.

Air Make-Up Unit (AMU)

It is necessary to replace the air exhausted that is exhausted from a spray booth. Replacement air can be drawn from the outside and filtered by an air make-up device if it is not drawn directly from the building.

A paint booth's temperature can be controlled with air make-up equipment during coating application and curing. Irrespective of the incoming, external air temperature, AMUs maintain a constant leaving-air temperature. For every cubic foot of air lost, they replace it with equal amounts of fresh air.

The paint booth is supplied with conditioned, filtered air by an AMU. As a result, there is no need to pull air from the building, which improves conditions for workers and saves money.

Paint Booth Manometers

Differential pressure gauges are available in various forms for measuring exhaust filter loading. Manometers, known as draft gauges or Magnehelic gauges, are used in most industrial spray booths.

The most popular "dirty filter" indicator is a manometer. Differential pressure gauges monitor the system’s airflow and indicate when paint filters are full and need to be replaced.

How a Spray Booth Functions

Spraying and drying are the two basic stages of activity. For safety and ventilation efficiency, the manner you work during the spraying phase should be the same. Clean air is drawn in from the outside and directed to the heat exchanger by an injection ventilator. The air is heated there before being directed to the spray booth filtering assembly. Then, depending on the spray booth equipment, it passes via the ceiling filters and enters the room in a vertical movement up and down.

It can also be "squeezed" through grates and floor filters before being pushed out through the building's exhaust ventilation channel (single inlet ventilator spray booth). It can also be pulled in by an extraction ventilator and expelled by an exhaust ventilation route over its buildings (extracting paint spray booths with two ventilator paint spray booths: inlet and exhaust). Because the air is so dirty, it cannot be used to heat the spray booth.

Individual gadgets act in different ways throughout the drying phase, caused by the necessity of reaching a significantly higher temperature of 140–158 °F (60–70 °C). Using a heating system with a typical heating efficiency, a temperature of 158–176 °F (70–80 °C) will be impossible to reach, though there are methods to solve it.

Portable paint booths draw air from the spray area, filter it, and return the filtered air to the spray area.

Specifications of Spray Booths

Spray finishing using flammable liquids is used in a variety of settings. Spraying flammable liquids causes them to atomize under pressure, making them more easily ignitable. If there is a fire or explosion, maintaining control of these hazards will help to safeguard employees and prevent property damage. In this chapter, the design and construction approved by the National Fire Protection Agency (NFPA), the fundamental specifications for a spray booth, will be explained.

Booth Construction and Design Specifications

The specifications during construction and design include:

- Non-combustible or limited combustible materials and assemblies must be used to build walls, doors, and ceilings that cross or enclose a spray area. They should be mounted or fixed securely and rigorously.

- Spray booth interior surfaces should be smooth and continuous with no corners and otherwise intended to avoid residue pocketing and ease cleaning and washing without harm.

- Air intake filters that are part of a ceiling assembly or wall must be ANSI/UL 900 listed in Class 1 or Class 2

- Aluminum must not be used for structural support elements, ceilings, or walls of a spray booth. Furthermore, aluminum must not be used for the spray booth's ventilation ductwork.

- If walls or ceiling assemblies are made of sheet metal, single skin assemblies must be no more than 0.05 in (1.2 mm) thick, and double skin assemblies must have no more than 0.035 (0.9 mm) thick sheets.

- Construction assembly with a one-hour fire resistance rating should be used to isolate paint spray booths from the rest of the structure.

- NFPA 101, Life Safety Code, requires enclosed paint spray booths to have methods of egress that fulfill the standards.

- Paint spray booths should be kept apart from other operations by at least one meter or by a fire-resistant barrier, wall, or floor/ceiling assembly with a one-hour fire resistance rating.

- Paint spray booths should be set up to make all of the spray booth's components easily accessible for cleaning.

Fire Suppression Specifications

An approved automated fire prevention system must be installed in the spray booth, exhaust ductwork, and the space behind the filters. Water, foam, gaseous agent, or dry chemical extinguishing systems are acceptable, but they must fulfill all NFPA regulations.

The system must sound a local alarm, halt all spray operations, and shut off any conveyors entering the spray booth. On any of the sprinkler heads, there should be no overspray. A thin paper or cellophane bag with a thickness of 0.003 (0.076 mm) inches should be used to cover them all. A qualified contractor must inspect and maintain all extinguishing systems.

Ventilation Specifications

Spray booths should have mechanical ventilation that can contain and eliminate combustible residues and dust and confine and control vapors and mists in a safe area. In addition, exhaust fans and motors should be nonferrous and explosion-proof.

The spray gun and the ventilation system should be connected so that the spray operations cannot occur until the ventilation is turned on and working. Filters must be changed in accordance with the manufacturer's instructions.

Electrical Specifications

Inside the booth, all electrical fixtures, switches, and junction boxes must be UL-listed and follow NFPA regulations. Additional electrical devices, such as fans, heaters, radios, portable lighting, electric cords, and equipment, should never be used inside the booth.

Chapter 2: Types & Configurations of Paint Spray Booths

Spray paint booths, like everything else in manufacturing, are tailored for specific applications. Models are available for little plastics, furniture, bikes, automobiles, aircraft, and boats, among other things. The spray booths can be classified by handling the airflow through the booth, filtering, and direction. All paint spray booths can be classified as pressurized, non-pressurized, or open.

Spray Booth Models

The different models or classes of spray booths are:

Open Face Spray Booths

Open face spray booths are a flexible and cost-effective solution capable of handling a wide variety of finishing and painting applications. Since they save on floor space, they make it easy to move products and parts in and out of the booth. With open face spray booths, unfiltered air enters at the front of the booth and flows horizontally through the booth flowing over workpieces and into the filter bank.

Lighting for open face spray booths comes in an assortment of configurations, with each method designed to meet the needs of an application. All open face spray booths have powerful fans and motors to create sufficient airflow.

The air from the spray booth exhausts through the plenum out of the building by an exhaust fan. Cold climates may require that the air exhaust be replaced in the building with make-up air that has been heated.

Pressurized Booths

Pressurized paint spray booths pull in more air than they exhaust, which increases the pressure in the booth. The positive pressure from the airflow creates a cleaner and more adaptable workspace. Control of the airflow changes the painting process and makes it possible to control the temperature, time, and booth pressure using the control panel.

The booth system is effectively and efficiently controlled so that the air's temperature and cleanliness flow smoothly and evenly. Pressure control is necessary to ensure that the air volume exhausted from the spray booth is the same as that supplied to it to create a balance.

Non-Pressurized Booths

Non-pressurized spray booths are enclosed booths that draw air through an inlet in the spray booth that has been designed to allow airflow. The inlet area has a set of filters mounted on the doors of the booth or a plenum. Air flows through the booth and is exhausted from the building by an exhaust fan. In cold climates, code may require that exhausted air be sent into the building with heated make-up air.

The configuration of non-pressurized booths allows for control of the air that flows through the booth. Cross-flow, semi-downdraft, side downdraft, and downdraft paint spray booths are non-pressurized paint spray booths.

Spray Booth Configurations

Pressurized and non-pressurized paint spray booths all come in a range of airflow configurations, each with its own benefits and drawbacks.

Downdraft Spray Booth

This type of booth is typically designed so the air flows into the booth through the booth’s ceiling and exits through the floor. Downdraft booths have a few styles that are commonly available on the market. The most common type of downdraft spray booths is pit-style booths that use an excavated pit and tunnel system for drawing air from the booth floor’s center portion.

The other types that are also quite common are raised floor or basement booths that draw air by grating the booth’s floor into a fabricated box that supports the booth’s entire structure. Few variations that integrate these two styles of paint spray booths can also be found in use. Each style and type of booth has applications it ideally fits. Sometimes a certain booth style or configuration may not be suitable for a particular application because of factors that are independent of the actual booth. Cases like that include not installing a downdraft booth in a shop with a ceiling that is insufficient in height for the accommodation of a typical booth structure.

Depending on each shop, different specific requirements must be met. However, in many cases, a shop must be equipped with a spray booth that will perfectly suit the shop production schedule’s needs and the required quality level.

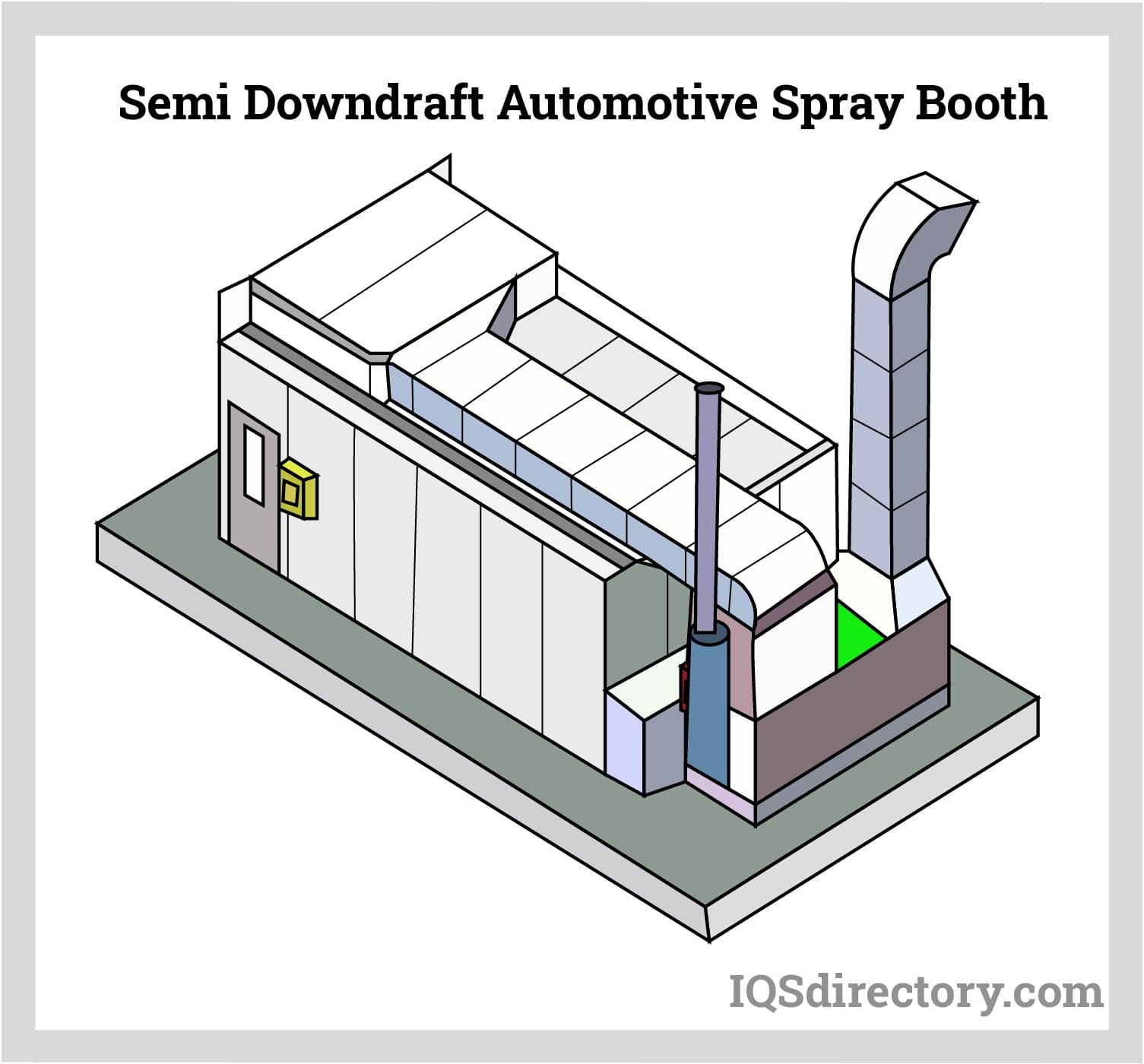

Semi-Downdraft Spray Booth

With semi-downdraft spray booths, air travels from the input to the ceiling of the booth and out the exhaust located on one side of the booth. The flow of air turns in a certain direction in order to flow out of the booth. Semi-downdraft paint spray booths are a hybrid between cross-draft and downdraft designs and have the best features of each.

Air enters a semi-downdraft paint spray booth through a supply plenum at the front of the booth. The fresh pressurized air is then released through the top of the booth and flows diagonally across and down towards the rear. Filters are at the rear of the booth and capture overspray before the air is exhausted as clean air.

Semi-downdraft paint spray booths have exceptional temperature control and air velocity flow control and can provide fresh or heated airflow using a heated air supply system. The main benefits of semi-downdraft paint spray booths are reduced overspray, removal of finish contamination, and low installation cost.

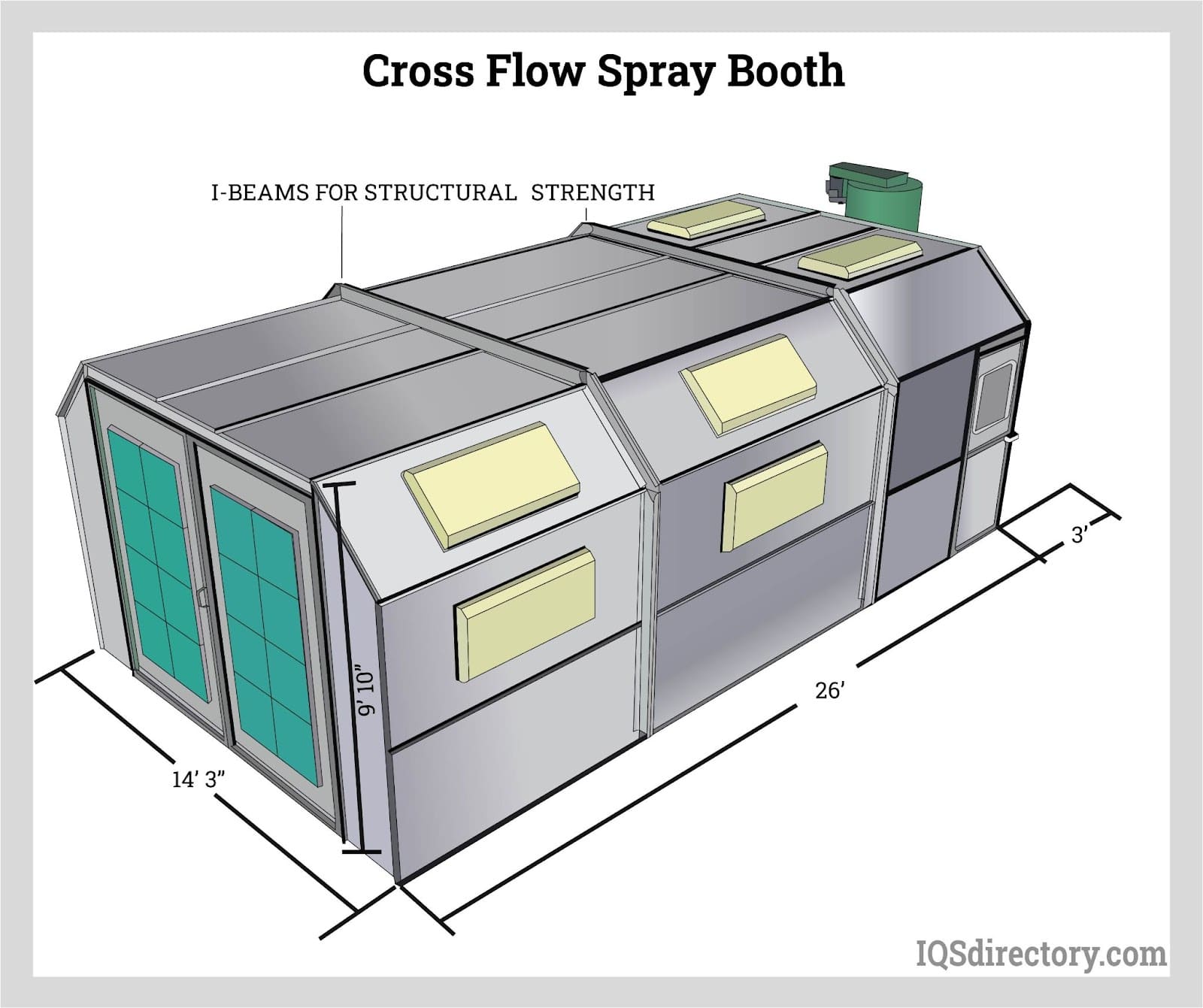

Cross-Draft Spray Booth

Cross-draft spray booths pull air horizontally over the workpiece. Air is drawn from the exterior environment through filters at the doors of the spray booth, which are intake panel filters. In some cases, cross-draft paint spray booths have air make-up systems that pull air from air make-up units located at the top of the booth. Booths with make-up systems have solid doors and filters on both sides of the booth.

Any overspray for a cross-draft spray booth is exhausted through exhaust filters, which collect paint particles. A secondary function of exhaust filters is to control paint buildup in the exhaust system to reduce possible fan and duct breakdowns.

Cross-draft paint spray booths have a horizontal airflow system that draws in non-pressurized fresh filtered air through the supply plenum. The horizontal airflow moves across the work area and out through the wall exhaust plenum at the opposite end of the booth. The design of cross-draft paint spray booths provides a clean and controlled work environment.

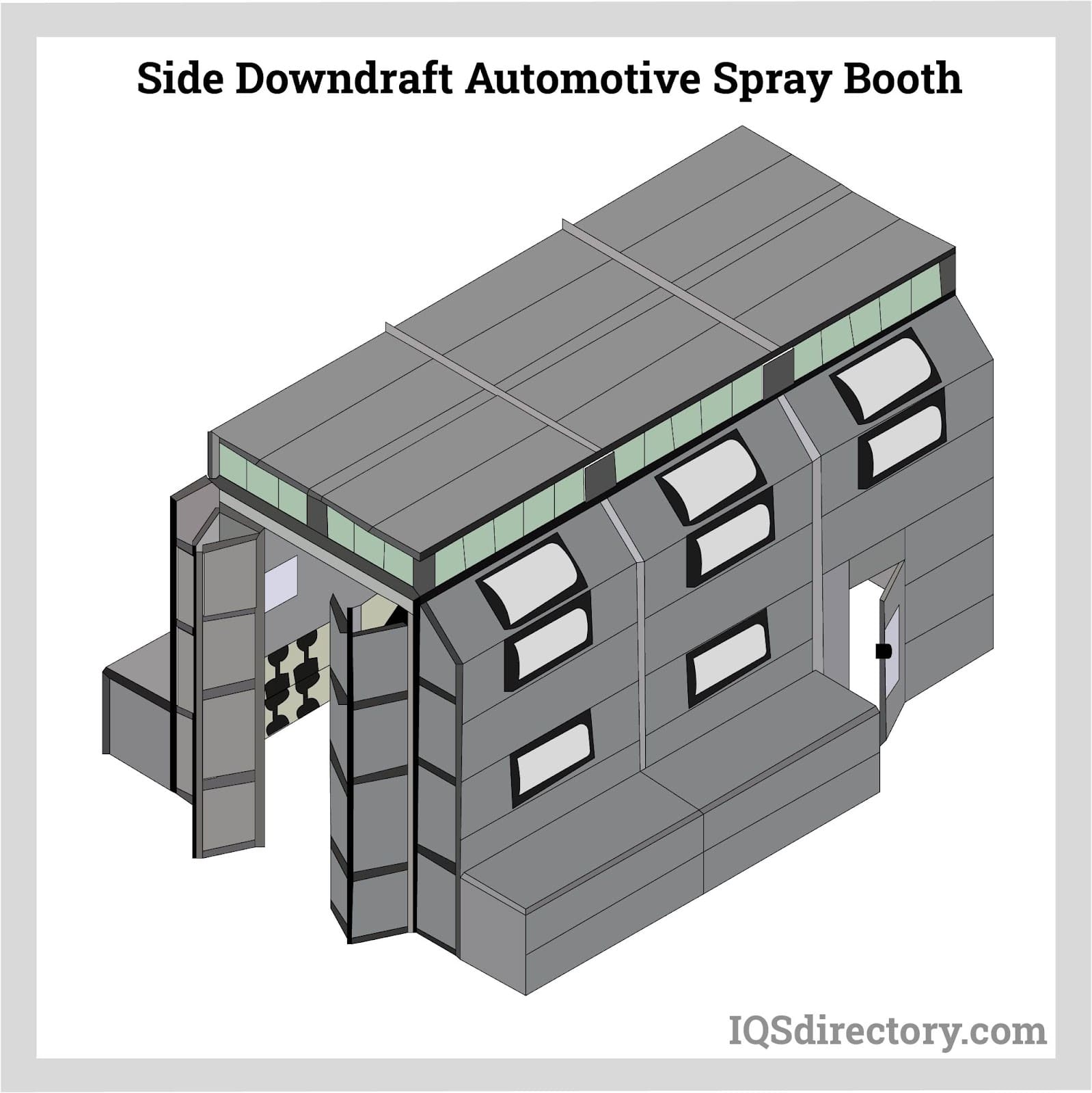

Side Downdraft Spray Booth

Side downdraft paint booths are ideal for shops that do not have a pit. Filtered air is drawn down into the booth from the ceiling to supply the inside of the booth with clean air. The movement of the air comes down the sides and walls of the booth that have exhaust fans and banks of filters to capture overspray.

The side downdraft paint spray booth design allows for an even and smooth flow of air on all sides of the booth cabin. There are several different configurations of downdraft paint spray booths, including an assortment of sizes as well as pressurized, non-pressurized, solid back, reverse flow, and drive-thru designs.

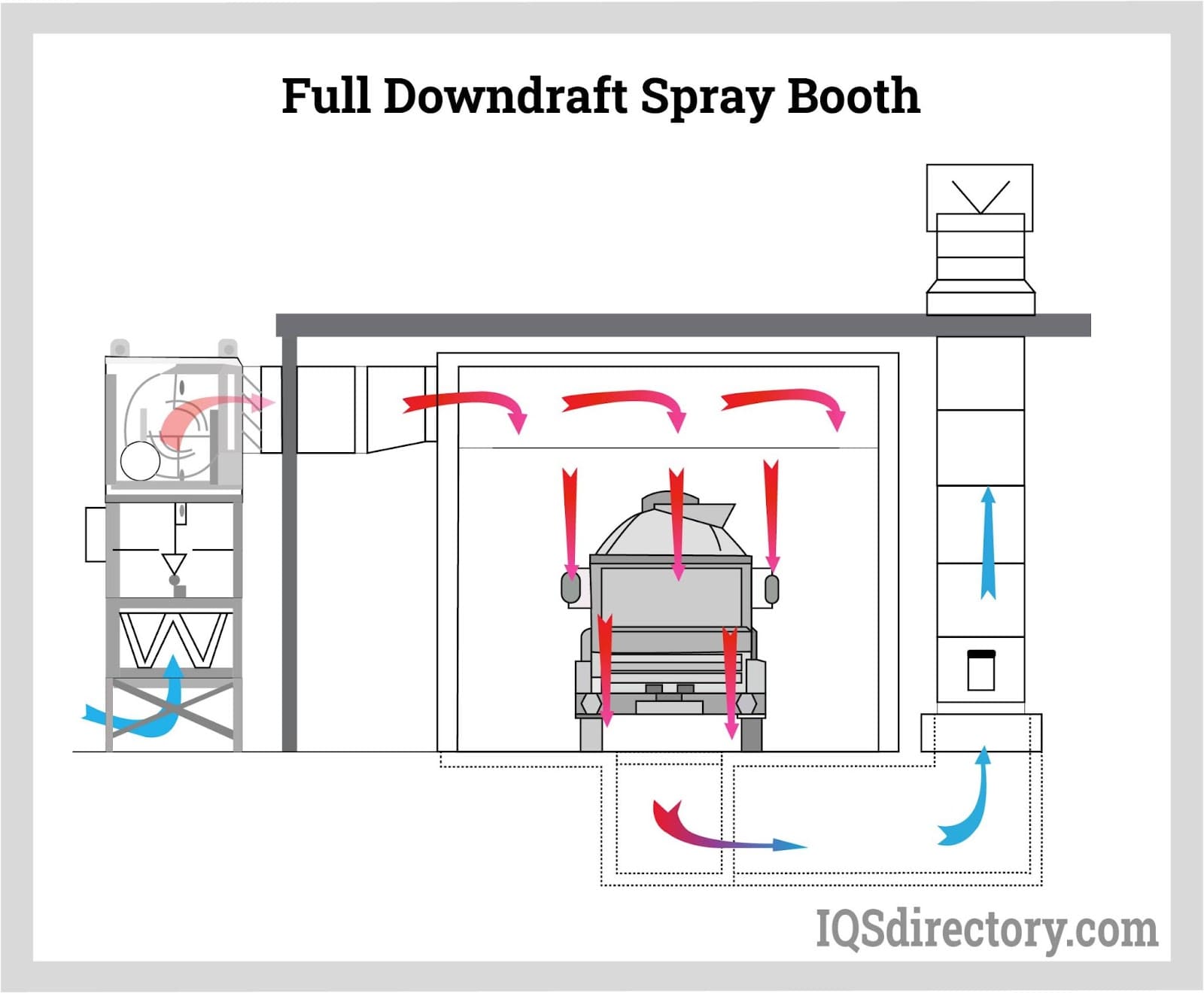

Full Downdraft Spray Booth

Full downdraft paint spray booths are the most popular paint booth design. The ceiling of the booth is filtered with diffusion filters that ensure the cleanest possible working conditions. Air enters through ceiling intake filters and is drawn down over the workpiece. A set of filters under the floor grating traps overspray such that clean filtered air leaves the paint spray booth.

The design of downdraft paint spray booths guarantees an exceptional workspace, excellent control of overspray, and a reduction of prep time.

The enclosed design of downdraft paint spray booths pulls overspray and contaminants down and away from the workpiece. Painter health guarantees the highest quality finish on a workpiece.

Several types of downdraft designs are available, including concrete pits and raised steel basements. They are believed to be the most efficient and cleanest paint spray booth option.

Cross-Flow Spray Booth

A cross-flow paint spray booth takes in air through a set of filters located in the doors of the booth and flows through the booth to exit at the opposite end. The unique and smooth design of cross-flow paint spray booths make it easy to have them expanded to fit varying paint applications.

Lighting and versatility are the keys to the success of cross-flow paint spray booths, which makes them the ideal choice for paint spray applications. The easy access and multiple configurations of cross-flow paint spray booths makes them ideal for a variety of painting applications.

Portable Paint Booth

Portable paint spray booths are self-contained and use a non-venting design that recirculates the air back into the spray area. Often referred to as mobile workstations, these booths can move throughout a facility to where they are needed. Smaller in design, a portable spray booth is normally used for painting smaller items or portions of vehicles or larger items. Most portable booths use an aggressive filtration system, including carbon filters, to remove particulates such as overspray as well as odors and vapors.

Dry Filter Spray Booth

These types of paint spray booths are designed to extract harmful particle emissions through an airstream which transports them to a filter medium.

The air enters from the intake filters of the ceiling, then clean air is drawn straight down around the painted parts and through a set of filters under the floor grating where the trapping of the overspray occurs and filtered air flows out of the booth into the atmosphere. This process ensures a superior working environment. This process also reduces prep time and controls overspray.

This helps to ensure a clean and healthy working environment that can comply with all requirements of current health and safety.

Water Wash Spray Booth

These types of paint spray booths provide an extremely efficient means for removing particles of paint from the exhausted air by utilizing water as a filtration medium. Water wash booths are used for paint usage of high volume.

To add on, water wash booths can handle a larger variety of paints than dry filter booths, with a broad range of viscosities and drying speeds. All health, fire, and building codes favor these types of spray booths. Water wash booths have more advantages over other booths, which are: flexibility and adaptability, appearance, and durability.

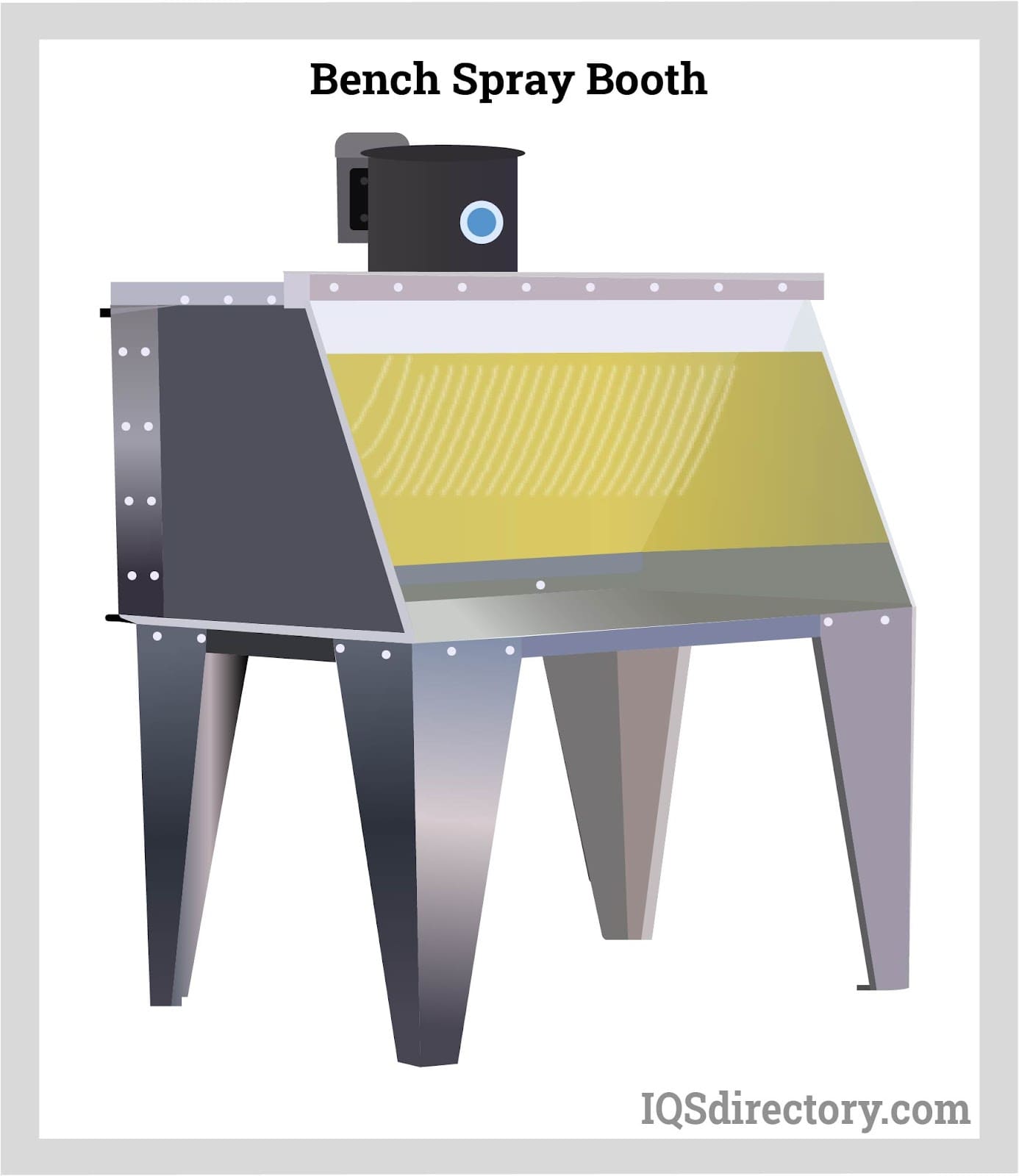

Bench Level Spray Booth

These types of paint spray booths operate under the similar principle as a full-size booth but with a convenient height of work surface to allow the painting of components that are small in size. All of the bench-level spray booths are 1 meter high and 1 meter deep and are manufactured with a fan and particle arrestment of high efficiency.

There are other types of filters that are available, like sloping. The booths are manufactured with mechanical protection to the underside of the fan. The standard fan suits a vertical run of ducting and the inclusion of on 90° bend. If more than one 90° bend is necessary, then there may be a requirement for the up-rating of the fan. The bench can be secured at a certain height that suits the operator, and a selection of work depths are there with either an angled filter or a vertical filter.

Paint Booth Accessories

Paint spray booths come with all of the necessary components that make them highly efficient and productive. In many cases, in order to configure a paint spray booth to the needs of a specific industry, various accessories and addons are required, which are supplied by all paint booth manufacturers.

Lighting

Lighting is one of the most important features of a paint spray booth, without which there tends to be shadows in the booth and the items being painted. Appropriate lit booths ensure that painters can finish their work in one smooth application without the need to rework a piece.

Much like other industrial applications, it is important that paint booth lighting complies with safety standards for paint spray booths. This includes electrical supplies that do not have the potential of causing the ignition of flammable materials. Under NFPA 33, paint spray booths are classified as Class I areas. Class I division 2 lights are sealed and gasketed to prevent the incursion of flammable substances.

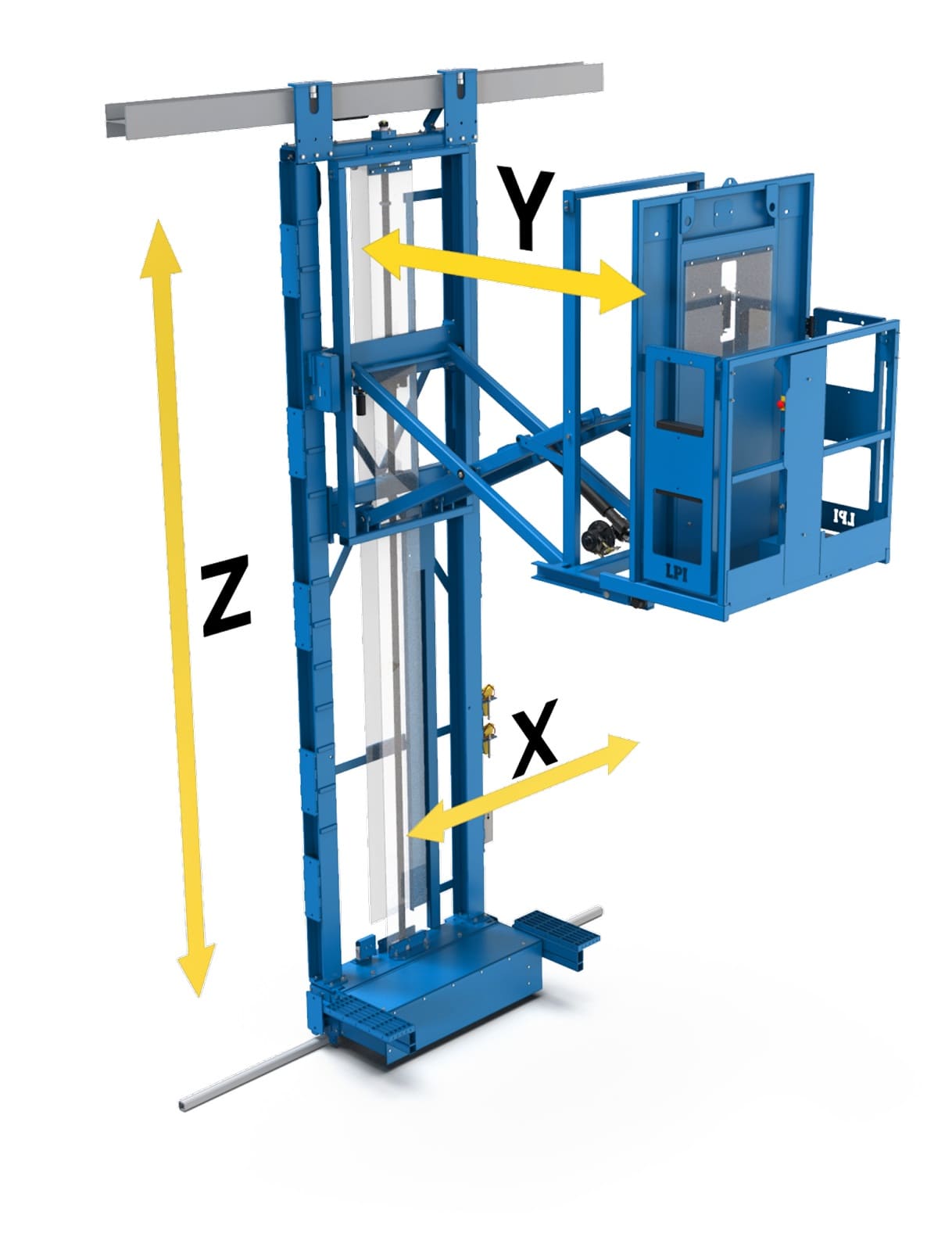

Lifts

Paint spray booth lifts are mast-based personnel lifts and come in various styles depending on the needs of a paint spray booth. They can be self-propelled, rail guided, have adjustable catwalks, and are capable of rotating on three or four axes. The wide assortment of paint spray booth lifts makes it possible to select the perfect lift to fit any type of paint spray application, from small projects requiring special positioning to large projects that need multiple height adjustments.

Hose and Gun Hanger

Hose and gun hangers come in several varieties with placement for one to several guns and multiple hose holders. They are normally positioned next to the hose connection and attached to the wall at a convenient height for easy access.

Test Panel Holder

The test panel holder holds a piece of paper or metal for testing paint spray. There are several ways to store a test panel holder with magnet ones for metal paint spray booths.

Booth Boxes

Booth boxes are convenient accessories for paint spray booths that make it possible to store guns, paint cups, gloves, tape, and other everyday use tools. There are several varieties of booth boxes with multiple shelves, doors, hangers, and organizers. They can be magnetic to be easily repositioned or permanently attached to the wall of a paint booth.

The few accessories listed above are a small sampling of the ones offered by paint spray booth manufacturers. Each type of accessory is designed to enhance and specialize the functions of a paint spray booth.

Leading Spray Booth Manufacturers and Suppliers

Chapter 3: Applications and Benefits of Paint Spray Booths

This chapter will detail the applications and benefits of paint spray booths.

Applications of Paint Spray Booths

The industries in which paint spray booths are applied include:

- Automotive

- Aerospace

- Large equipment

- Industrial manufacturing

Benefits of Paint Spray Booths

The benefits of paint spray booths include:

Controlled Environment

Paint spray booths offer a controlled environment when finishing a vehicle’s paint job. There are some factors that can affect the finish of a vehicle's paint job, like humidity, temperature, and dust.

Control Hazardous Materials

Automotive paints and other materials used in the process of painting often contain hazardous chemicals and release particles and fumes that can damage the health of people and the environment. Spray paint booths have the advantage of isolating and removing these chemicals to ensure that they don’t pose a threat to the areas that surround the work area.

Dust-Free Surroundings

An immaculate paint finish is achieved by eliminating dust floating about. An even coat of paint on the bare material is achieved by a lack of dust, without any debris or dust particles landing on the wet surface. The durability of the paint and coatings is also increased.

Longer-Lasting Finish

The controlled environment allows a more stable application of the base coatings and the paint, which will bring more durability. When the air temperature is maintained, an even layer of paint can be applied to the car, resulting in a smooth finish. To add on, these controlled conditions allow the paint and the coatings that are added to bond together very well, creating a strong coat.

Abide by Regulations

The regulations required by the environmental protection agency can be met or exceeded regarding the dangerous chemicals involved in spray painting. The employees can be kept safer by the limitation of their exposure.

Reduced Costs

If you have the right paint spray booth, you can reduce the required costs for its operation. Coating quality that is improved can also reduce material and labor costs. In addition, fewer layers and touch-ups may be needed to be used.

Considerations When Choosing a Spray Booth

The considerations when choosing a spray booth include:

Spray Booth Size

There are multi-bay paint spray booths as well as single-stall booths available. The dimensions of parts to be painted and the available space should be considered.

The dimensions of the largest section to be painted, including racking, pallets, and trolleys, must be considered. To establish the size of the booth, add a minimum of 2 feet (60 cm) to the height and 4.9 ft (1.5 m) to the length and breadth. When painting multiple components at the same time, around 2.95 ft (90 cm) is to be left between them.

Spray Booth Price

A completely new spray booth with every feature will cost quite a bit, for example, a high-quality downdraft booth. In this case, it's necessary to look for reasonably priced booths that still meet the requirements.

Spray Booth Features

Filters are an important feature of any paint booth because they keep fumes and overspray from escaping and damaging the environment. The sort of filter used will be determined by local requirements as well as the paint in use.

Fans may help circulate air and are beneficial for keeping the air in the booth clear. The majority of the features were covered in the previous chapter. Adding more features will inevitably raise the price.

Spray Booth Environmental Protection Compliance

When it comes to environmental protection, there are a few regulations to follow when spray painting. This is why an actual spray booth is required over erecting a few tarps.

The legislation in a painting location should be known before looking for a booth that meets the standards. Before acquiring a booth, it's a good idea to familiarize yourself with the rules.

Spray Booth Draft Types

In a paint booth, the air must circulate, but where it circulates will either aid or hinder painting efforts. Fans and filters suck and expel air, depending on which end of the draft they are on, to keep the air moving. The most popular options will be discussed.

Tips for Using Paint Spray Booths

Using a spray paint booth is all about creating an environment that is right in terms of temperature, air pressure, and humidity, and also containing and safely removing harmful toxins and fumes. The steps listed below must be followed to achieve this:

- Prior to a spray job, it is important to check that the booth itself and the equipment of the booth are clean and correctly working. It is essential to ensure that the air pressure inside the booth and air pressure of the spray gun, as well as the pattern of spray, are all set up correctly. The filters must be serviced regularly. The exhaust filters used for exhaustion will become clogged over time with overspray, and intake filters become clogged from outside elements like dust.

- When spraying the paint onto the vehicle, make sure that you are spraying near the vent supplying air. Ideally, you should be closer to the air vent than the spray paint gun, to allow the blowing away of any overspray from yourself and towards the exhaust fan.

- There must be a thorough cleaning of the panels before entering the booth in order to prevent taking dust in with you.

- Protective gear must be kept on until you get out of the booth, as the fumes can harm you.

- To help minimize dust in your paintwork, the booth walls need a tacky coat and wet floor.

Conclusion

Spray booths are specially built enclosures for the housing of spray equipment. Spray booths isolate vapors produced during the spray painting process, thereby protecting the environment from harmful chemicals present in the spray paints. There are different types of spray booths made from different types of materials. But as already mentioned, using a spray booth is all about creating an environment that is right in terms of temperature, air pressure, and humidity, and also containing and safely removing harmful toxins and fumes. It is important to clean the booth itself and the booth’s equipment and make sure that they are functioning correctly.